A Beautiful Façade requires a Robust Support System

Our FastClad Brick Slips Systems offer a range of brick finishes to meet the demands of the modern building designer, but what sits behind this façade is equally needs to be equally beautifully engineered.

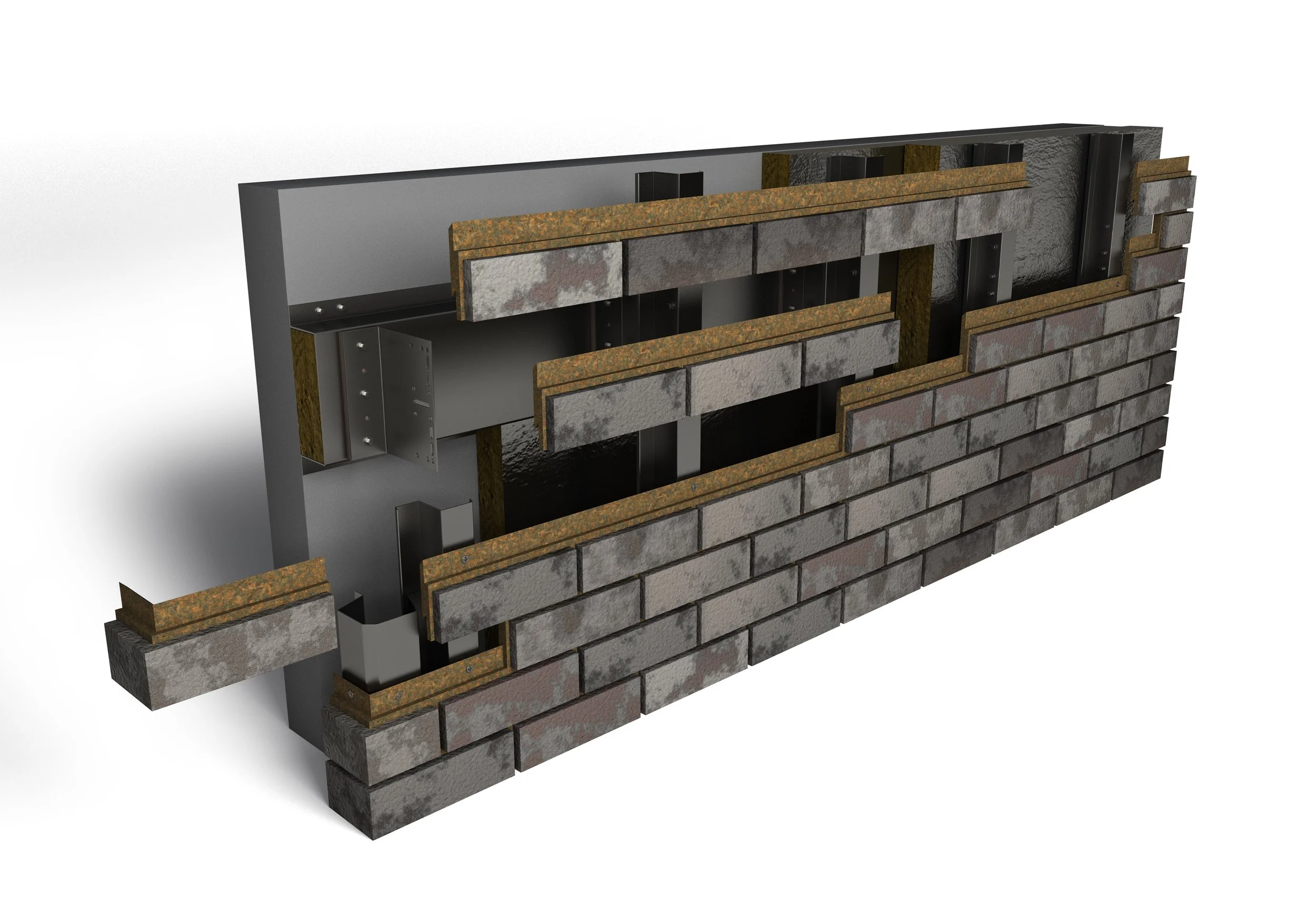

Typical Steel Support Installation for FastClad

Buildability Built In

Many systems look good on paper, but when it comes to installing on a live construction site with its inherent tolerance issues and accessibility, it can become difficult to install as per the drawings and the support system may not be as robust as it is intended to be.

Our Tritherm Handi Bracket System for FastClad was developed in 2017 by Architectural Profiles Limited and manufactured by them in the UK ever since.

Typical build up with Tophat, Isopad and Helping Hand Brackets

A horizontal tophat is fixed through the face of the face of the SFS panel into the structural members behind.

Insulation is placed within the Tophat and Helping Hand Brackets are fixed to the Tophat with a 12mm ISO Thermal Insulation Pad to act as a thermal break.

Vertical Zed Rails are fixed to the Helping Hand Brackets which allow adjustment to maintain a vertical facade

Insulation is then placed into the cavity and pinned to the outer sheathing board before the vertical carrier Zed Rails are fixed to the Helping Hand Brackets, which ensure that there is a satisfactory drained and vented cavity maintained.

Fire Barriers

Intumescent Fire Barriers are installed between the supports, and due to the flat-back nature of FastClad, will provide a clean closing of the cavity in the event of a fire.

The FastClad Panels are fixed to the vertical Zed Rails via the upstand flange onto which the next course locks.

The façade is gun pointed with a lime mortar and the result is a ‘real brick’ façade which can be relied on to function effectively due to the robust carrier system and simple installation parameters.