Why Would You Choose A Bonded Brick Slip System?

FastClad has been at the forefront of adhered brick slip systems, initiating a close partnership with Structural Adhesives Ltd in 2013 which has enabled us to develop our 100% factory bonded products to the point where they hold independently assessed minimum service lives of 60 years, which is unheard of for any brick slip system.

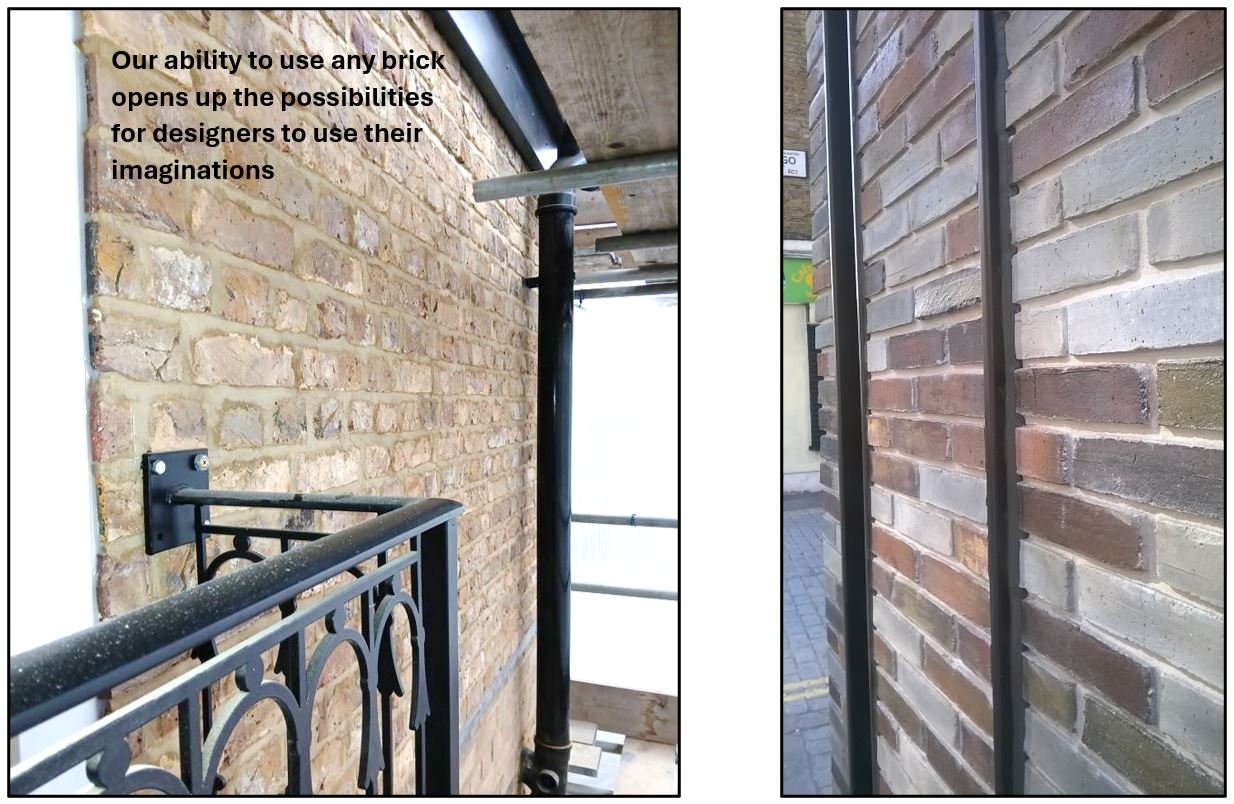

The range of bricks that can be used by bonding is not limited by their manufactured tolerances, unlike mechanical fix rail systems which can only use T2 (+/-2mm) tolerance bricks. We often use T1 and Tm bricks which can exceed +/-3mm, such as the bricks above.

Bonding across the rear face of the slip spreads the load across the whole area of the slip and does not rely on a small proportion of mechanical contact area which means that fragile bricks, such as clamp fired stocks, can be used without fear of the slip coming loose if it cracks.

Here at FastClad we carefully manage cutting waste, our slips only require one cut, which is carefully managed with two methods of cutting, which will be driven by the structural integrity of the clay in the brick.

All components are factory bonded which ensures that the adhesive application is consistent, and that curing takes place in a controlled atmosphere, why not come for a factory tour and see for yourself.

Bonded systems are not constrained by brick dimensional tolerances and can even use reclaim bricks.

Utilising Fragile Bricks

The actual tensile strength of cut slip should also be considered but this is not something that is generally published for a cut slip, but bricks that are clamp fired or demonstrate a very low compressive strength are generally not suitable for mechanical fix systems for two reasons, one the cutting of the initial slip then followed by cutting two grooves into the slip edges can cause the slip to deteriorate and become weak, consequently their ability to withstand the point loading of rails can be seriously compromised.

Which System to Choose

In summary, both systems have their applications and both methods, when specified, manufactured and installed correctly, will exceed their certified service life, and the ‘bonded slips systems fall off’ is an opinion based on incorrectly installed projects of the past.

The key to a successful install relies on the manufacturer, installer and specifier to ensure that it is the correct solution for their project.